Sustainability Is The Foundation Of Trangia's Brand Values

Long before sustainability became a buzzword in environmental conversations, it has been the foundation behind Trangia since the company was founded back in 1925. Trangia products are still manufactured in Trångsviken, a small village located in northern Sweden. This makes it easier for them to secure their high-quality standard and adapt quickly to change.

Long product lifecycle and access to spare parts is the cornerstone of Trangia’s brand values.

Production

From Raw Materials to a complete TRANGIA stove in six minutes.

There are 50 different stages in the production process of a Trangia stove. Altogether, they make up a total of six minutes. With 60 years of experience and constant development work being carried out on both tools and methods use, Trangia is getting pretty good at what they do.

Trangia is continuously striving to develop new and better ways to manufacture their products. With limited factory space they are forced to streamline and make production more efficient.

Carbon Footprint

During the manufacturing process, a Trangia stove creates a carbon footprint of 14 kilos, with raw materials being the largest contributor responsible for 85% of the emissions. With the average product lifecycle extending over 20-30 years, 14 kilos is considered relatively low. The stove, being almost solely made from aluminum, is also easy to recycle and turn into new products once it has served its purpose. Due to aluminum being an energy intensive raw material, our material contains 50% recycled aluminum.

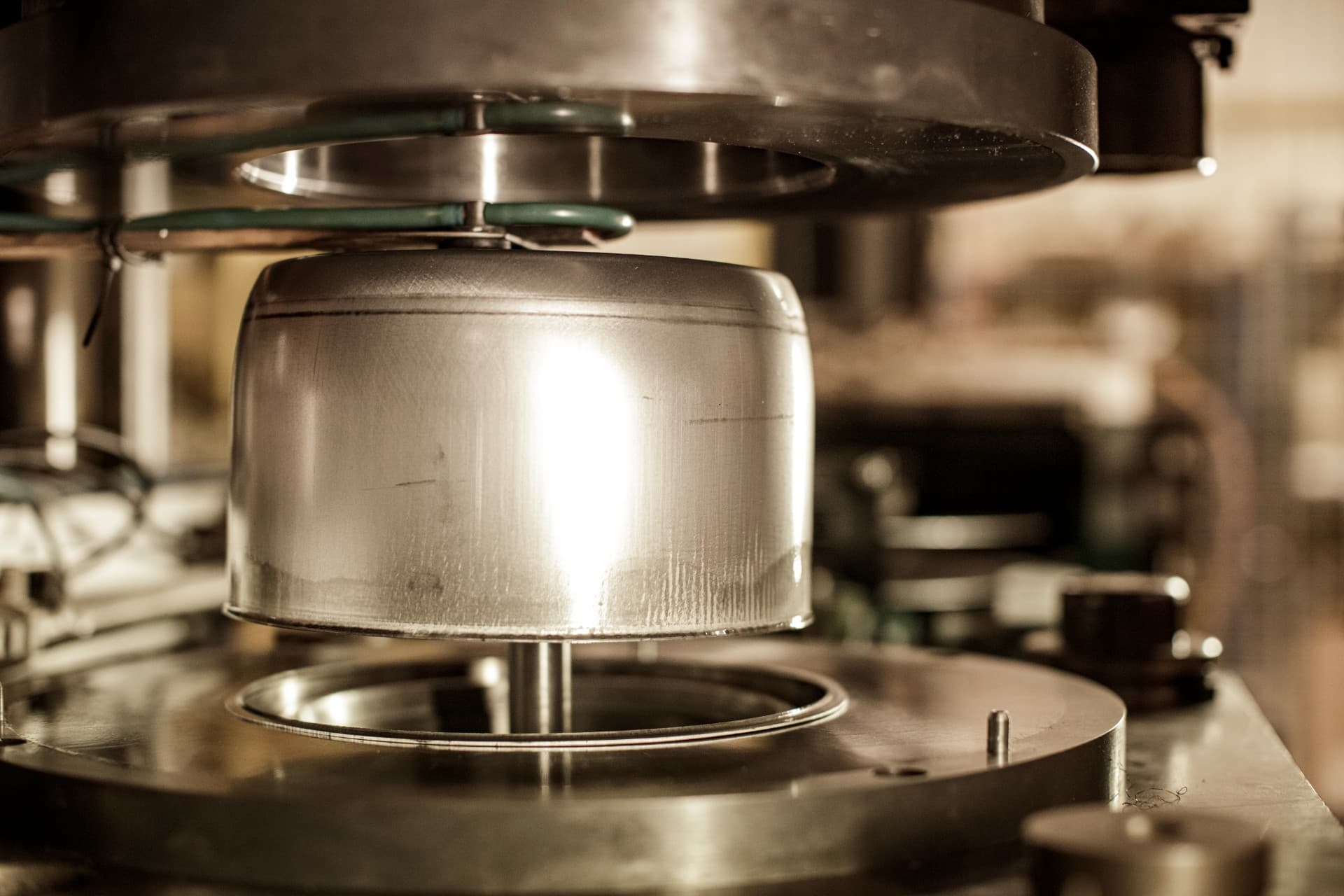

Trangia gets the aluminum delivered to our plant in pre-cut discs in order to minimize off-cut scraps. Then the pot is shaped with 50- tons of pressure in a hydraulic press.

The Trangia factory is heated with pellets from forest residues and powered by electricity from 100% renewable sources.

As a company, they are continuously working on turning their negative environmental impact on the planet into a long-term positive one.